Your full service global supplier of innovative plastic packaging solutions.

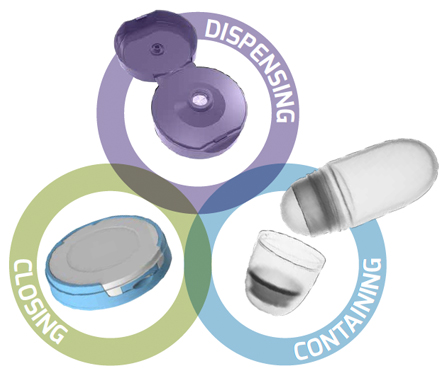

Weener Plastics is a full service global supplier of innovative plastic packaging solutions, with a strong focus on the functionalities DISPENSING, CONTAINING and CLOSING.

The company designs, develops and manufactures added value Caps, Closures, Roll-on Balls, Jars and Bottles for the Personal Care, Food, Home Care and Health Care markets.

Headquartered in Ede, The Netherlands, the company employs about 2000 people and has 24 facilities in 16 countries worldwide.

The Plasticum facilities joined Weener Plastics in 2013. Plasticum's unprecedented innovation strength and Weener's unrivalled technological competences offer a unique global, full service proposition.

It is our ambition to be your preferred global supplier of innovative and added value packaging solutions. We serve as a reliable full service partner to customers in the Personal Care, Food, Home Care and Health Care markets. Respecting our corporate social responsibility, we strive for fast growth with long term and constructive relationships.

A commitment to quality leadership permeates Weener's quality systems. We meet the required standards with mature systems that are rigorously audited and calibrated with industry expectations on a continual basis. Weener's quality teams have a rich understanding of global regulatory and industry trends.

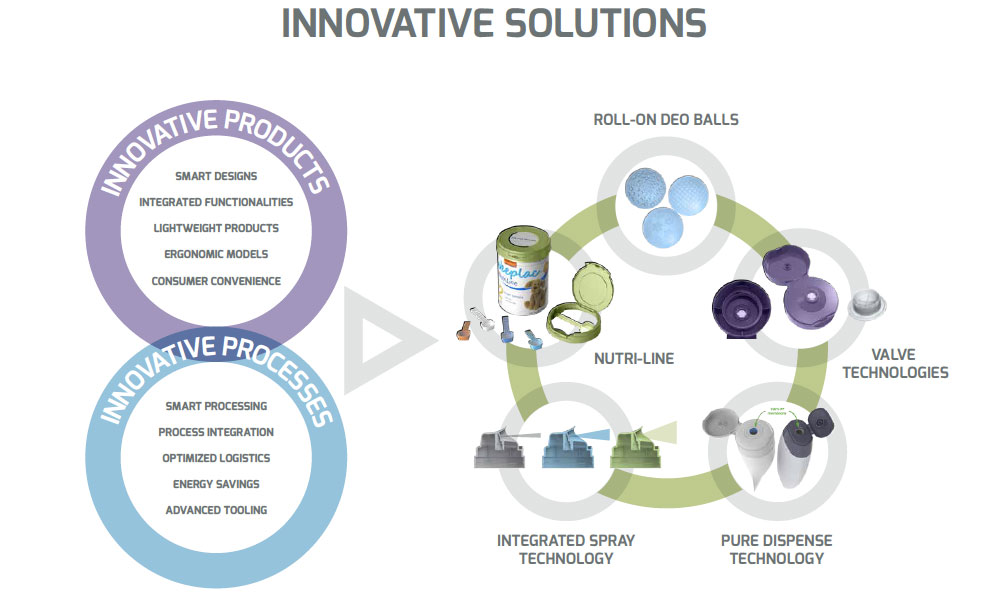

The focus on both product and process innovations empowers us to be the most inventive partner in the rigid plastic packaging market. Customers get smart product designs, advanced tooling techniques and efficient processes that enable our customers to fulfill their market potential. Many innovative products and technologies are patented and protected.

The Innovation & Development teams, including engineering, contribute to the innovative nature of our company. They have a wealth of experience in designing, developing and engineering the most efficient and sustainable solutions. Our in-house mold shop produces high-quality molds for advanced molding technologies.

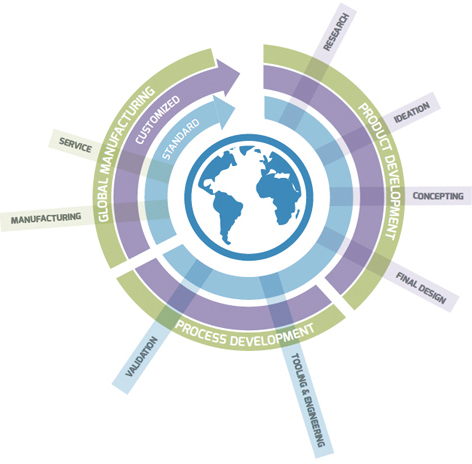

Our unique range of services enables us to cover the whole process from concepting and tooling to series production and OTIF deliveries. The in-house tool shop and global production network give Weener a leading position in the rigid plastic packaging industry. Our customer focused services connect with eminent national and international brand owners.

All areas of the process chain are staffed with highly qualified employees who take every opportunity to optimize product development, engineering, manufacturing and logistic processes without sacrificing quality and sustainability. Whether you have a conceptual idea or a final product design, our experts can convert it to a first-class high volume product.

If you are a brand owner in the Personal Care, Food & Beverage or Home Care market, we are the right partner for you. Weener offers tailor-made packaging solutions as well as innovative standard products that can be rolled-out to other countries and continents. Our global network of production facilities enables to deliver a consistent and professional service that you need to fulfill your customers' requirements.

Weener's Global Key Account Managers are experienced to handle large and complex projects in multinational environments. They manage multinational customers that expect to be serviced and supplied worldwide in a professional, consistent and co-ordinated way.

Our Project Management teams are experienced to handle large and complex packaging projects. They have the right expertise to develop and transfer high-cavitation tools and complete system solutions. They are committed to deliver the highest quality while honoring environmental aspects.

Sustainability is an integral part of Weener's strategy. We take measures to reduce our own carbon footprint and we help customers to reduce theirs by offering more sustainable solutions. Our goal is to be environmentally friendly throughout the whole value chain.

Environmental conscience is embedded in our whole organization. Green energy, light weight designs, integration of product functionalities, efficient processes, sustainable purchases and smart logistics are just some examples that show the commitment of the whole organization.