WE DELIVER

on the promises made to our

customers, our employees and

all other stakeholders worldwide

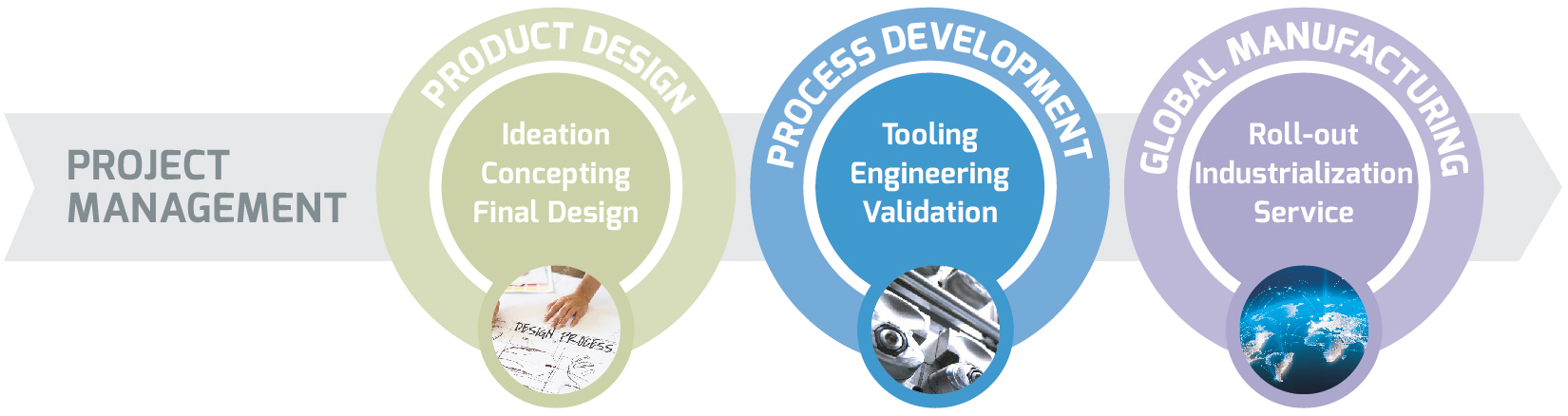

WP offers full support in the complete packaging value chain, from ideation and concepting to global manufacturing. Customers can rely on our innovative products and processes for standard as well as for customized products.

WP is a proven molding and processing expert relying on many years of knowledge and experience. We cover all aspects of the manufacturing process as required by global brands, local brands and private labels.

Commitment to quality leadership permeates WP's quality systems. We meet required standards with mature systems that are rigorously audited and calibrated to industry expectations on a continual basis. Weener's quality teams have a far-reaching understanding of global regulatory and industry trends. Our group has the following accreditations:

Providing quality products to customers and delivering on our CSR, environmental, and eco-efficient production goals requires a safe, hygienic work environment. We realize this by stimulating and rewarding the right behavior, guided by leadership, and by providing the required assets and optimizing the workplace.